LASER DEPARTMENT

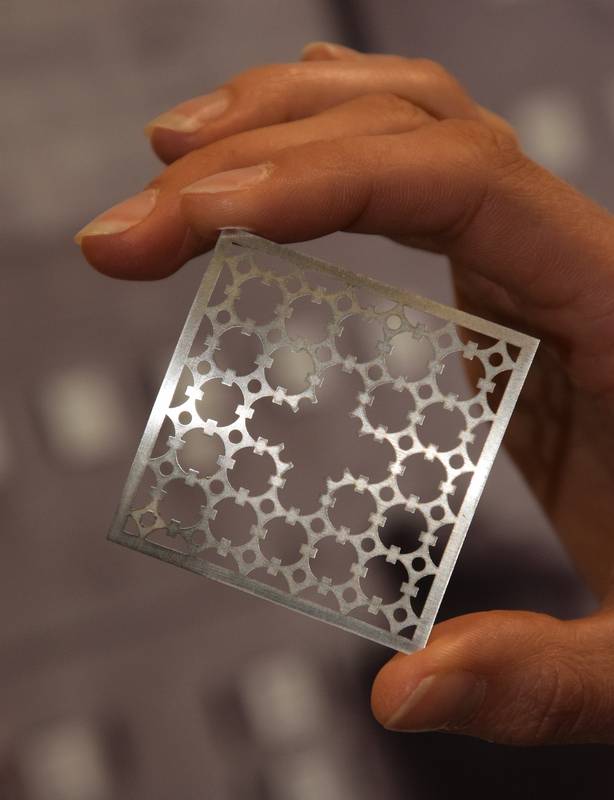

Ino-Tech Laser is your single source for virtually any laser materials processing application. From R & D to production, our engineering and technical staff can handle your requirements. The Ino-Tech Laser engineering and service team provides custom LASER CUTTING, WELDING, DRILLING, MARKING and ABLATING services and can act as your precision component contract manufacturer. Our custom laser workstations house cutting edge laser technology and decades of engineering experience to meet precision and intricate designs. For laser welding, cutting, drilling, ablation and marking: Ino-Tech Laser’s vast applications experience and years of processing expertise has earned us the reputation as a complete outsourcing solution.

Laser machining is the core competency of our business. Thin wall tight tolerances is our NICHE business model. Tube or Flat application - ON-AXIS or OFF-AXIS. We can execute. Prototypes in 3-5 business days flat. We strive to meet your desired price point and timelines on each and every project we undertake.

Consider us as your extended LASER SOLUTIONS APPS LAB.

We have developed specific programming, processing techniques and laser parametres/recipes that enable us to efficiently laser cut designs that our competition cannot execute. Whether your design is an intricate, tight tolerance, fragile part, or a tube with a few features with wide tolerances, we can make cost-effective parts to your specifications, in prototype and production quantities. In addition to laser cutting of tubular materials (both on-axis and off-axis), we also offer laser cutting of small parts from flat materials up to roughly .050” thickness.

Laser Range: INOTECH LASER PROCESSING puts the client’s application requirement as the driving force and crux of their business. INOTECH LASER PROCESSING provides the best and most optimum micro-machining solutions to our clients. Here are a list of various LASER TYPES, WAVELENGTHS and POWER RANGES our team has worked with so far. This reflects the vast expertise that you the customer will be in the presence of.

Ino-Tech Laser is accustomed to providing tight tolerance laser cutting and processing of thin-wall tubular metal components, sub-assemblies and implants drilling, welding, marking and ablating solutions for a wide range of industries, fulfilling both prototype and production needs of our clients.

We utilize the following laser technologies:

- 3 x Ytterbium Fiber Laser Systems (1064nm) welding systems

200W-300W (ON and OFF-AXIS - 5 x Ytterbium Fiber Laser Systems (1064nm) cutting and drilling systems

200W-400W (ON and OFF AXIS TUBE and FLAT cutting systems) - 3 x Disk laser Systems (1030nm – Q-Switch) laser cutting system

50W (Tube cutter) - 1 x Ytterbium Fiber Laser System (1064nm) laser marking system 20W

- 2 x UV Laser System (355nm) cutting, marking, and micro-drilling system 20W

Applications:

- Micromachining cardiovascular stents

- Resize silicon wafers for solar panels

- 2-D profile cutting in sheet metals

- Cutting automotive hydro-form tubes, cradles and side pillars

- Tube cutting

- 3-D cutting

- High pressure clean cutting of stainless steels and aluminum

Materials:

HYPOTUBES:

- PEEK

- Stainless Steel

- Nitinol (NiTi)

- Cobalt Chromium

- Titanium

- Tantalum

- Hastelloy

- Magnesium

- Elgiloy

- Platinum

- Gold

- Silver

- Brass

- Copper

FLATS SHEETS:

- PEEK

- Stainless Steel

- Mu Metal

- Inconel

- Nitinol (NiTi)

- Cobalt Chromium

- Titanium

- Tantalum

- Hastelloy

- Magnesium

- Elgiloy

- Invar

- Kovar

- Platinum

- Brass

- Copper

- Gold

- Beryllium Copper

Material Sizes For Laser Cutting:

- Material (Wall) Thickness = .002” - .050”

- Tubing Diameter = .008” - .700” O.D.

- Tubing Length: We can accommodate most tubing lengths from 1 inch to 10 feet.

- Flat Cutting: small parts only, up to roughly 1” maximum dimension.

Cut Width (Laser Kerf Width):

- Thin Wall Materials (.002” - .005”) Kerf = .0005” - .001”

- Regular Wall (.006” - .009”) Kerf = .001” - .002”

- Thick Wall (.010” & larger) Kerf = .0015” - .004”

Calculating Part Yield from Raw Material:

- Part Yield Per Tube Length = (Supplied Tubing Length - 6”) / (Part Length + .015”) (for tubes longer than 6”)

- Tubes smaller than 6” would be manually loaded on a fixture