Laser Micromachining

TUBE and FLAT - CUTTING, WELDING and ETCHING systems:

- 3 x Ytterbium Fiber Laser Systems (1064nm) welding systems

200W-300W (ON and OFF-AXIS - 5 x Ytterbium Fiber Laser Systems (1064nm) cutting and drilling systems

200W-400W (ON and OFF AXIS TUBE and FLAT cutting systems) - 3 x Disk laser Systems (1030nm – Q-Switch) laser cutting system

50W (Tube cutter) - 1 x Ytterbium Fiber Laser System (1064nm) laser marking system 20W

- 2 x UV Laser System (355nm) cutting, marking, and micro-drilling system 20W

Laser Applications:

- Micromachining cardiovascular stents

- Laser Cutting OPTO-Mechanical shims

- Resize silicon wafers for solar panels

- 2-D profile cutting in sheet metals

- Cutting Medical grade PEEK and Polyethylene

- Wet and Dry Tube cutting

- Tube and Flat Laser Welding

- Gas Assisted Laser cutting

- Laser Etching

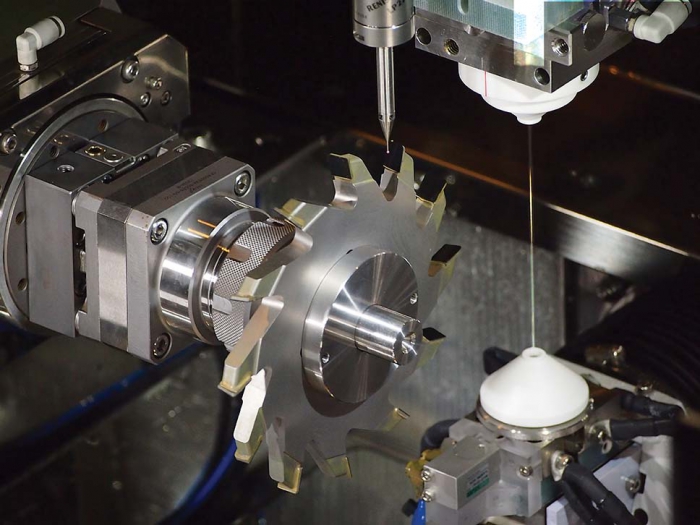

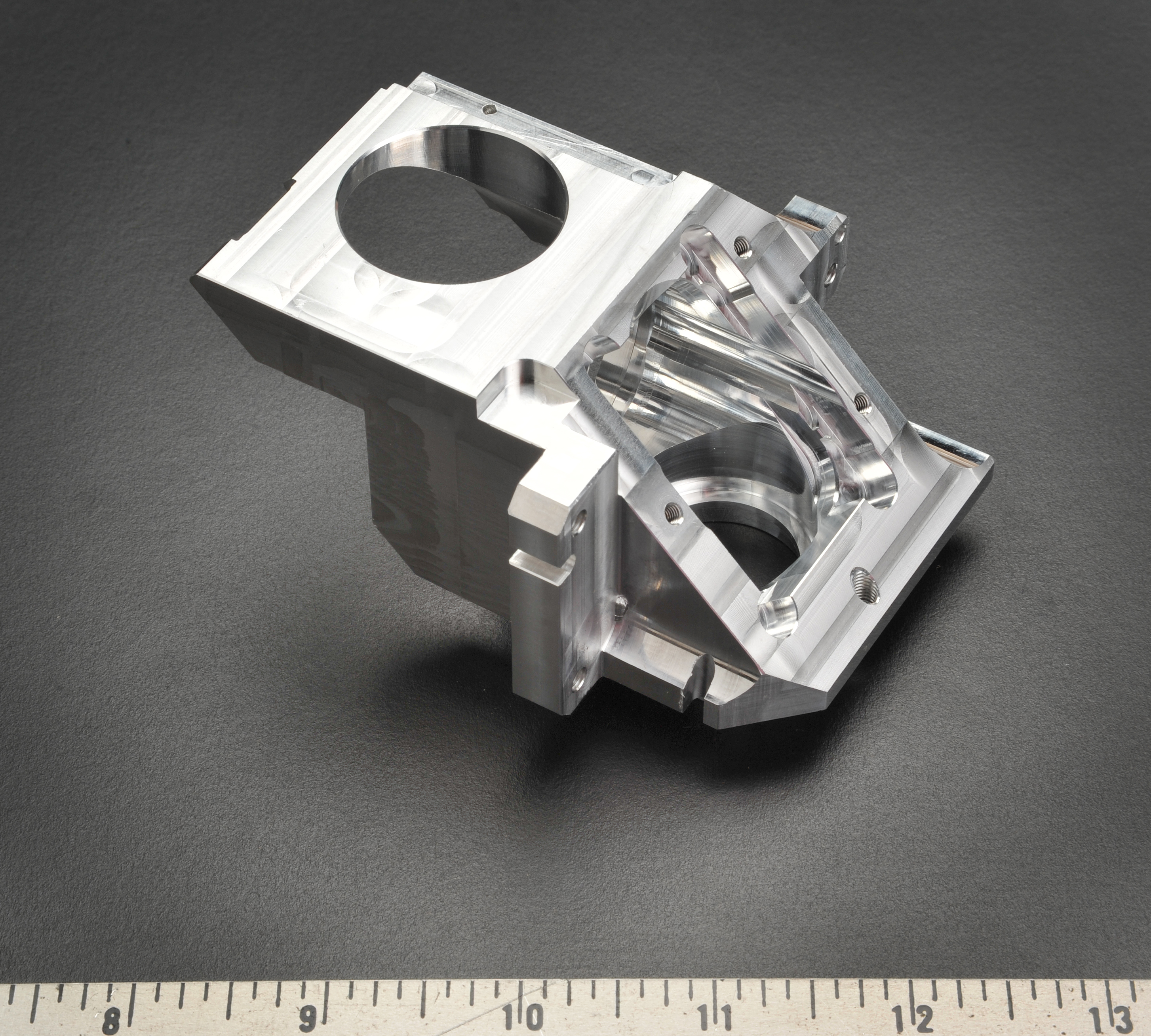

5-AXIS MACHINING

Does your company currently rely on 3-axis machining? While 3-axis machining has its benefits, it does pose certain manufacturing limitations. The primary difference is that 5-axis machining introduces the element of rotation of the A and B axes. In addition to enabling faster production of complex shapes, the 5-axis parts production process results in a higher-quality surface finish. Other important 5-axis CNC machining benefits include:

Shorter lead times:

The enhanced capabilities of the 5-axis machine results in decreased production times, which translate into shorter lead times for your production projects. This allows you to provide better service to your customer base.Greater accuracy:

5-axis machining and milling offers a level of precision that 3-axis processes cannot replicate, which is crucial if your finished products must adhere to strict quality and performance specifications. 5-axis machining also eliminates the need to move the workpiece among multiple workstations, thereby reducing the risk of error.Use of shorter cutting tools:

It is feasible to produce high-quality 5-axis machined parts with the use of shorter cutters, which can reduce the vibration that frequently occurs when machining deep cavities with a 3-axis process. This typically results in a smoother surface finish. The use of a shorter cutting tool also allows for a higher cutting speed without putting excess pressure on the tool.Creating new business opportunities:

Many companies find that 5-axis milling increases the types of products and services they can offer to their customers and prospects. This enables them to capture a larger segment of the market and take their entire business operation to a whole new level.As many as 60 percent of the parts produced in CNC shops these days require five-sided machining. As such, 5-axis milling and machining services are in high-demand for various applications in a wide range of industries. A primary consumer of 5-axis machining services is the aerospace industry, where machined parts must be designed to conform to the aerodynamic shapes found in most types of aircraft. 5-axis production parts are also key components when manufacturing products for the food processing, pharmaceutical, medical and energy production industries

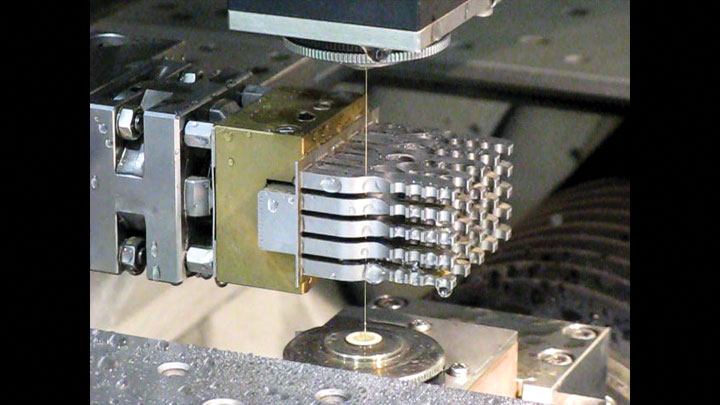

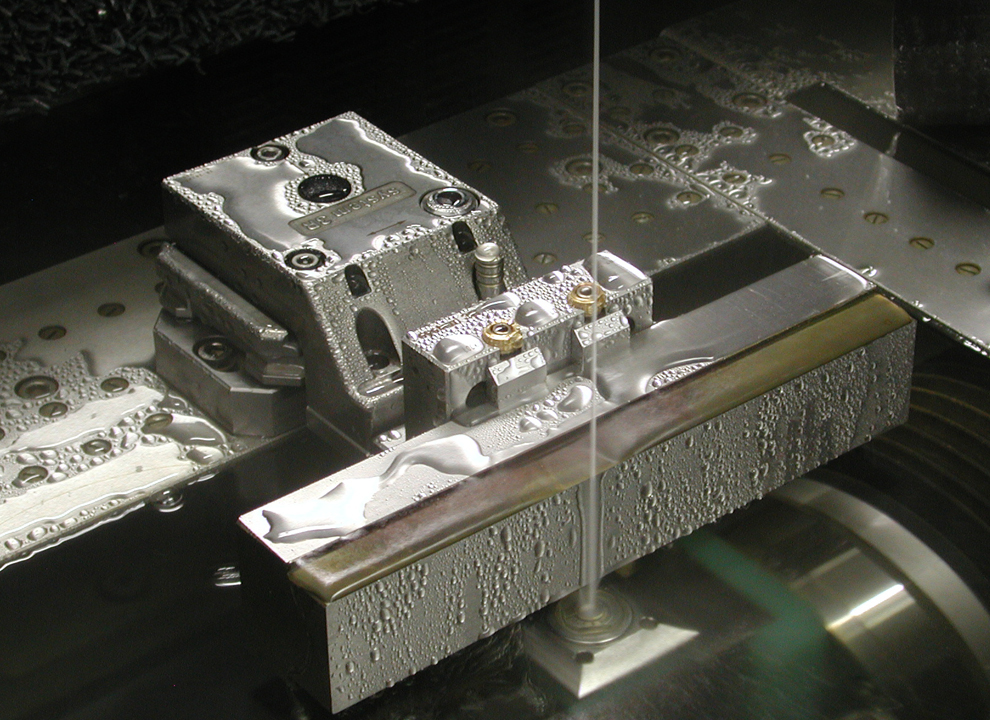

Wire EDM

Wire EDM is a cutting operation that utilizes a Computer Numerically Controlled and electrically charged brass wire to “burn” through a raw block or stack of material, producing an extremely accurate cut and clean finish suitable for aerospace and medical applications.

INOTECH LASER has the capability to manufacture production parts and tooling components of tight tolerance by utilizing Wire EDM. We specialize in production runs of precision components and tube cut offs, creating fixtures, building spare tooling for metal stamping dies, and sharpening shaped die components.

We use Wire EDM for customer contract work as well as our internal requirements. INOTECH LASER can assist your company with its Wire EDM needs from design assistance to final completion. Fixtures used for production runs are designed by our talented Design Engineering Team and built by our experienced toolmakers. Our programmers use CAD information to produce high-volume and low-volume Wire EDM parts in our state-of-the-art Wire EDM machines and to our customer’s custom specifications.

Wire EDM @ INOTECH LASER is a core component of our Tool & Die maintenance and repair capabilities. Our Wire EDM department supports our Maintenance Department by providing sharpened or replacement tooling components in order to repair a worn or damaged tool. All jobs that enter our Wire EDM department are analyzed by our Quality Assurance Department to ensure that all dimensions are correct and geometries have been met. Blocks are checked for squareness and absolute size. In-process SPC data collection is utilized to maintain quality in production modes.

We currently run 4-axis machines capable of wire diameters from .004″ to .012″ Our machines have a cuttable travel (XYZ) of 20.5″X 14.5″X 12.0″and minimum corner radius of .0023″ as necessary. We have the capability of working with material in our machines up to 2200 pounds. Wire EDM machine accuracy to within .0001″ repeatability to .00005″ INOTECH LASER also has one CDM Drill which allow holes to be drilled as small as .012″ or as large as .250″with a maximum work piece height of 8.0″

Our WIRE EDM equipment include:

- 4 X SODICK WIRE EDM – A325

- 1 X SODICK EDM AQ 535L

- 1 X SODICK AQ 300L

- 1 X SODICK K1C

- 1 X SODICK WIRE EDM - AQ327

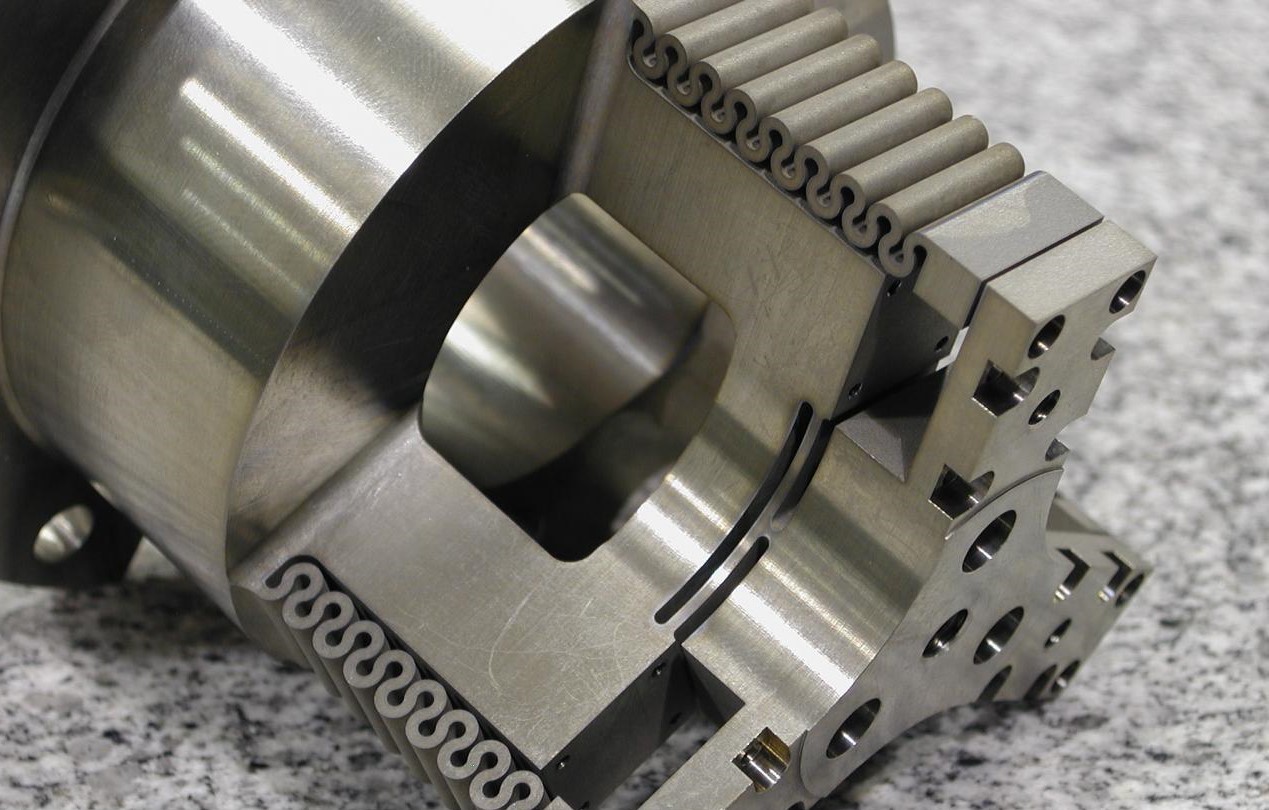

Complex Parts

We take pride in providing machining solutions for HIGHLY COMPLEX PARTS holding very tight tolereances and PROFILES. Our ONE SHOP MACHINE STOP has every machining solution under one roof. 5-AXIS MACHINING, WIRE-EDM, LASER MICRO-MACHINING, CNC MILLING, CNC LATHE... whatever your machining needs...Reach out to INOTECH LASER PROCESSING INC.